SPOILER ALERT!

Johnson Wedge Wire Screen Filter Element

A quick introduction johnson wedge cord display style company distributors suppliers ◊ The business with the largest export volume of wedge wire display filter items in North China( 3 consecutive years ). ◊ Three technical patents( handling modern technology and

cleansing technology). ◊ Five wedge cord screen filter assembly line, 2 filter component parts assembly line, the intro of smart production tools, stringent control of product top quality. ◊ The professional technical team can supply wedge cable display style solutions, CAD as well as 3D drawings for consumers. ◊ Independent top quality inspection department, from the purchase of basic materials to the delivery examination, each web link has an unique high quality evaluation employees, offering item assessment certificate. ◊ Accumulated greater than 20 years of manufacturing experience, acquainted with the use of products in

different markets, can give specialist suggestions to consumers. Our devices Wedge wire display welding equipment V wire drawing devices & Corrective tools Argon arc welding, plasma welding, laser

welding, resistance welding, and also smart arm welding devices Laser cutting and also molybdenum cord reducing devices Milling maker and CNC equipment Stamping tools and also rolling tools Cleaning up tools

Innovation and also expertise are our business society. We just focus on the R & D as well as manufacturing of wedge net product series.

The invention of products is our objective. We are devoted to becoming the first brand name of steel filter elements in China. ATM MACHINE Specifications of high precision all-welded wedge cord tube & pipe wedge cord rotating screen trommel screenIn order to resolve the problem of poor

satiation and unequal space of wedge cable screen tube, the bonded wedge cable display tube( wedge filter element) separately developed by BLUSLOT ™ FILTER has outstanding roundness as well as absolute void. Product: stainless steel ss304, ss316, ss316l, double 2205 as well as numerous other special alloy materials. Specs: 25, mm, 30mm, 36mm, 42mm, 45mm, 50mm, 60m, 65mm, 70mm, 76mm, 80mm, 86mm, 89mm, 110mm, 137mm, 189mm, 268mm, 305 and lots of other requirements. Minimum port dimension: 15 microns Port size: >/= 10 microns. Tolerance: 5 microns. The minimum size of the bonded cable covered screen pipeline: 25 mm. Maximum diameter: 1800mm. Size: 2300mm.

The raw materials are unified right into

top notch wire products.

The Vee cord filter element made by BLUSLOT FILTER is made up of V-shaped steel cord( account cable) and also assistance wire. Due to the special wedge wire framework, compared with sintered wire filter aspect and various other filter aspects,

it has the advantages of not easy to blockObstruct easy very easy backwash and long service solution, and as well as the perfect best

for other filter elementsVarious other Wedge cord screen applications( usage) wedge cord screen basket companyA wedge wire display is primarily made use of for industrial purification as well as separation.

Our wedge cable display filter products can be related to a lot more exact filter systems. The wedge wire display has high impurity holding capability, high porosity, long life span, strong plasticity as well as mechanical

toughness, exact filtering system precision, as well as strong permeability. It is an ideal filter element with high accuracy as well as high temperature level.

Wedge wire displays can be used as spread cooling product in a high-temperature environment, as well as pore plate material for gas circulation or fluidization bed. A wedge cable screen filter is a perfect filter aspect for filtration, splitting up, and dewatering. Key efficiency and features of

Johnson screen.

Its wear resistance is 3 to 5 times that of common screen plate as well as even more than five times that of average screen plate. The maintenance work is tiny, Johnson screen filter is hard to be harmed, and also its life span is long. With consistent constant port framework, steady

welding top quality, high open area rate, lengthy solution life, high toughness, steel, and also bearing capacity, different steel screen filters can be made. The items are made from high-grade stainless

steel( 302, 304, 304L, 316, 316L, etc.) product and bonded by innovative processing technology, with stringent innovation. Johnson screen is different from a normal stainless-steel cable woven mesh. It has the advantages of antiskid, high solidity, excellent flexibility, compression resistance, vibration resistance, rust resistance, hard to block, small, not affected by temperature, long service life, low extensive price, and so on. The space size is strictly uniform, the opening rate is high, the testing as well as filtering modern technology is good, the space dimension can be randomly chosen, and can be refined right into different shapes of screening filters. Johnson level screen is a type of metal mesh made use of for screen filtration. It is an integral part of the testing procedure. Each screening maker shall choose a display plate that satisfies its working requirements. Material characteristics, structure, material, screening maker criteria, screening capacity, evaluating effectiveness as well as procedure thickness of the screen plate. As a result, it is required to choose the sieve plate according to different materials as well as positions to attain the screening impact. ♠ How to clean wedge cord screen filter, cylinder, basket & cartridge? bonded wedge wire display pipe technologyHow is wedge wire display items cleaned? Do you understand? Let's discuss it by the service technicians of the wedge wire screen makers.

I hope it can aid you. In the passivation film on wedge cord display surface area, matching response is created as a result of self-excited response,

resulting in the formation of little openings, near to each other of chloride ions, creating a strong corrosive option, thus increasing the corrosion reaction price. Intergranular deterioration splits still exist in stainless-steel, all of which will certainly damage the passivation film on a wedge wire displays. The appearance of stainless steel shall be cleaned up on a regular basis to maintain its stunning appearance as well as extend its service life. When cleansing the stainless-steel surface, pay attention to stay clear of surface area scrapes, and prevent using bleaching ingredients and also abrasives, steel balls, grinding devices, etc. In order to cleanse the cleaning agent, please wash the surface area with clear water and also complete the cleaning. Stainless-steel is closely pertaining to individuals's every day life. With the growth of the economic situation, the wedge cable display is much more and also more prominent. Numerous people know little about the properties of stainless steel, let alone the upkeep of stainless steel. Lots of people believe stainless-steel will certainly never corrosion. In fact, stainless steel just has great corrosion resistance. The factor is that passive film is developed on the surface area, which exists in the kind of even more secure oxide in nature. In various other words, stainless-steel is oxidized according to different service problems and also different oxidation levels. This phenomenon is typically called rust. Weak detergent or warm water washing, stainless-steel look trademark, film, rolling stainless-steel display surface dirt, very easy to get rid of dirt soap. Scrub with warm water, weak cleaning agent, adhesive, alcohol or organic

solvent( ether, benzene). The stainless steel surface area is contaminated by oil, lubricating substance, and oil. Clean it with a soft towel, then wash it with neutral detergent or ammonia remedy or special detergent, and also wash it immediately with clear water. Stainless steel surface area has

bleach and also different acid attachment. Then wash with ammonia or neutral salt carbonate solution, as well as clean with neutral cleaning agent or cozy water. ATM MACHINE What is the reason of the breakage of the account wire display? cord wrapped screen knotted wedge cable screenWhat's the factor for the damages to the account cord screen? Let's discuss it to you by the specialists of the account cable display distributors. I wish it can assist you. There are several factors for the damage of the account wire display, such as the unqualified quality of the cord mesh, the buildup of materials, the incorrect instructions of the oscillating motor and so forth. Just how to manage these concerns? Initially, pick the account cable display with professional high quality

. The top layer of the screen is very closely incorporated with the lower layer of the stress layer. The tension innovation of the display is utilized. Otherwise, when the stress and anxiety layer is tight, the drilling cuttings might not be released. When choosing the profile cord display, we should recognize the factory of

the profile cable display, and after that the high quality of the goods. When the profile cable screen is used to adjust the rotation direction of the motor, if the electric motor of the profile cord screen turns in the direction of the internal

side wrongly, although the projection angle is additionally ahead, the cuttings have the force to curtail, so the forward motion rate of the cuttings will significantly reduce. In serious instances, the cuttings may not be released usually. When it is made use of, the wedge wire mesh should avoid faults as a lot as possible. In order to prevent product build-up, the profile cable screen ought to be well arranged as well as protected at average times. ATM MACHINE How to replace the shaking wedge cable screen? The circular shaking display is a widely utilized basic screening device. How to transform the shaking wedge cable display quickly? The height and size of the equipment are not extremely huge. In order to minimize the trouble of display transforming and simplify the process of display changing as long as possible, we upgraded the vibrating wedge cord screen framework when designing the shaking screen. U-shaped groove grid structure. The better benefit of this grid is that it permits customers to complete screen replacement in 3 minutes. Fast, time-saving.

Take out the revolving display framework as well as place it on the screen framework. Eliminate the embossing strip, get rid of the currently busted display, open the recently prepared brand-new display,

and then as well as after that put the main screen without display. In order to take care of the screen, the brand-new screen size is normally concerning 2cm bigger than the called for dimension.

Cut off the remaining 2 cm display along the side of the screen

frame, structure keep as well as at the edge of the screen. Place the sealer strip taken out of the screen bag back to the initial direction of the screen, so as to reset the screen and slowly remove the frame, put the diaphragm ring back on the display, hit the circumference of the diaphragm ring evenly with a soft hammer, as well as tighten the copper nut of the diaphragm ring. There is a portable maintenance film on the surface of the wedge wire screen, and the upkeep of the oxide movie can improve the reliable service life of the wedge cord display panels.

Chemical technique: utilize a pickling passivation paste and also normal temperature level cleaning solution with not natural ingredients for immersion.

So as to attain the goal of bleaching the natural color of stainless steel. Sandblasting( shot) approach: it is generally to spray mini glass grains to remove the black oxide skin on the surface of the stainless steel sieve plate. In order to adjust to the setting, a safety movie will be coated on the surface of the wedge wire display filter throughout the handling and also manufacturing, so as to stop the corrosion of

the stainless steel item. ATM MACHINE Wire wrapped display laying. Before laying the cable covered display, we must initially make the installment plan of the wedge cord mesh. When laying stainless steel cord covered screen, the laying directions shall be offered according to the actual site as well as the area solution of equipment specialists. When the thickness of the reinforcing mesh is not enough to be turned, much less

than 1-2 enhancing bars can be welded at the end of the strengthening mesh, and after that both ends of the enhancing mesh can be punctured into the light beam, and also the straight bar field binding approach can be utilized for reinforcement.

For reduced straight reinforcement, cable ties will be used at each joint where the support is attached to the welded textile. For both ends of the bonded wire mesh that need to be pierced into the light beam, when the longitudinal instructions of the cable covered screen is fairly slim, very first usage the bending contortion feature of the wire covered display to flex the facility of the welded cable mesh upward, to ensure that the ends can be pierced into the beam one at a time. In between the ends of two bonded grids, the smaller sized overlapping length of the steel bar lap joint shall not be much less than 1.3 times of the

smaller sized anchoring length. In the overlapping location, the wedge-shaped mesh of each welded transverse reinforcement need to not be less than the distance in between

the external bars in between one and two wedge-shaped mesh will not be much less than 50 mm. When among the two-wire covered display grids in the overlapping area has no transverse support, the smaller overlapping size of the ribbed wire covered screen grid shall be 1.3 times of the smaller sized anchorage

size La, as well as shall not be much less than 300 mm. When the diameter of the longitudinal stressed out support in the overlapping location is d ≥ 10 mm, the overlapping length will be boosted by 5d. There are two techniques for the bottom mesh of the cable wrapped display: vertical support as well as floor covering mesh placement. The surface area reinforcement mesh of two-way support with a welded mesh of ribbed reinforcement will embrace the level erection method. It needs to be placed in a place with a small force and also kept at a certain range. Besides the 1/ 4 clear period of the beam side, the overlapping size in overlapping instructions will not be much less than 30dd, and also the diameter of support

will not be less than 250mm. These are the issues that must be taken notice of prior to laying wedge-shaped cable mesh. If you have something you don't know, you can directly connect with our customer support department, and also we will certainly offer you wholeheartedly. ATM MACHINE What's the effect on the wedge cable screen filter rate? Product. Wedge wire display is widely utilized, so there are three kinds of resources for it: carbon steel resources, stainless steel raw products, and also plastic anti-corrosion basic materials. The rate of a wedge cable display differs with various resources. The much better the raw products, the greater the cost, the higher the equivalent list prices. The change of the raw material costs will certainly affect the price of a wedge wire screen. The rates of different basic materials differ considerably. The price of duplex stainless steel made use of in salt water purification is much greater than that of SS304 or SS316. Along with the distinction in the rate of raw products, it is hard for the dual-phase steel to be drawn into a V-shaped triangular cable for wedge cord mesh. Handling innovation. Wedge cord screen's processing modern technology plays a decisive duty in its top quality. In order to make sure premium testing, we require to refine all parts as well as plan the

whole, so regarding guarantee efficient testing. Kinds. Wedge cable displays can be separated right into different forms as well as kinds according to the size of the display surface: rectangular and round. Various sorts of screened products have various capacities. The larger the quantity is, the bigger the screen weight is, and the greater the price is. ♠ What are the bottom lines of making use of wedge cable screens at heats? Wedge cord screen has the attributes of heat resistance, acid resistance, corrosion resistance, use resistance, and so on, so generally, it is heat-resistant, as well as will not impact its life span at high

temperature level. However, due to different production procedures, the solution life of the wedge wire displays made by various makers is different. As a result, the adhering to issues ought to be thought about when using it at a high temperature level. The warmth produced by friction at work. As a result of different production processes, the thermal growth coefficient of the wedge cord

display is additionally various. When various products are welded together, there will be the opportunity of thermal exhaustion. When the ambient temperature level is

over 400 ℃, the periodic reduction triggered by the development between parts should

additionally be totally thought about. Creep. Common cord mesh has hot brittleness when it functions at heat, so does a wedge cable display. Silicon, graphite, and also molybdenum disulfide lubes have great heat resistance.

ATM MACHINE Comparison of the determined value of pressure drop in between the Johnson wedge cable screen and also woven wire mesh. In the oil and also chemical market as well as other industries, the filter screen is extensively made use of in the procedure of fluid transport.

In the last few years, Johnson's wedge wire screen has actually replaced the standard woven mesh and also orifice plate a growing number of, which is mostly identified by the one-of-a-kind structure and also numerous benefits of the wedge cable displays. In a specific series of pores, the fluid resistance decline of Johnson vee

wire display is clearly smaller than that of the woven net and pore plate structure. The computation as well as contrast of resistance decrease in the style and option of filter screen products are of excellent value for the selection of filter screen. Filter aspects of chemical pipeline filters, grids of reactors, dryers, and so on shall be evaluated. When the liquid passes

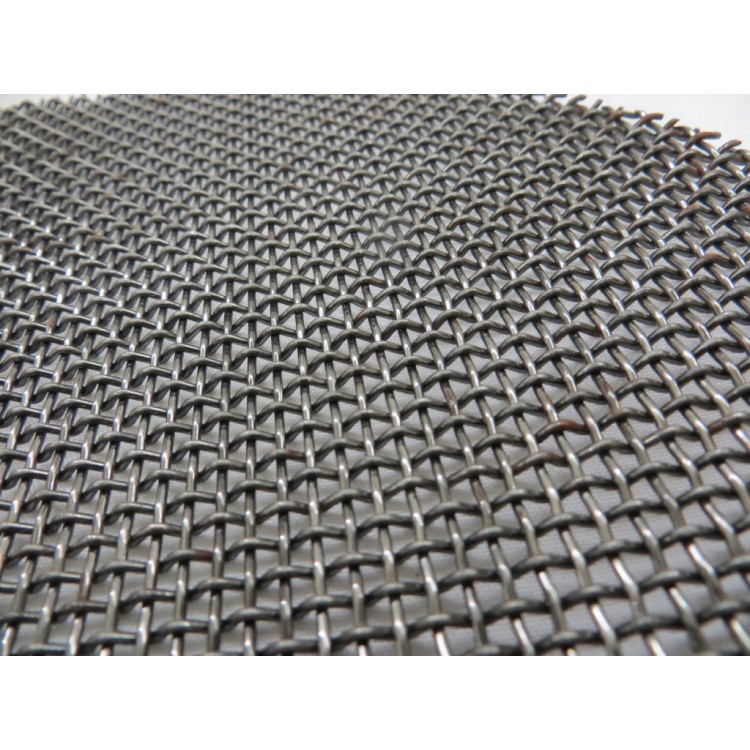

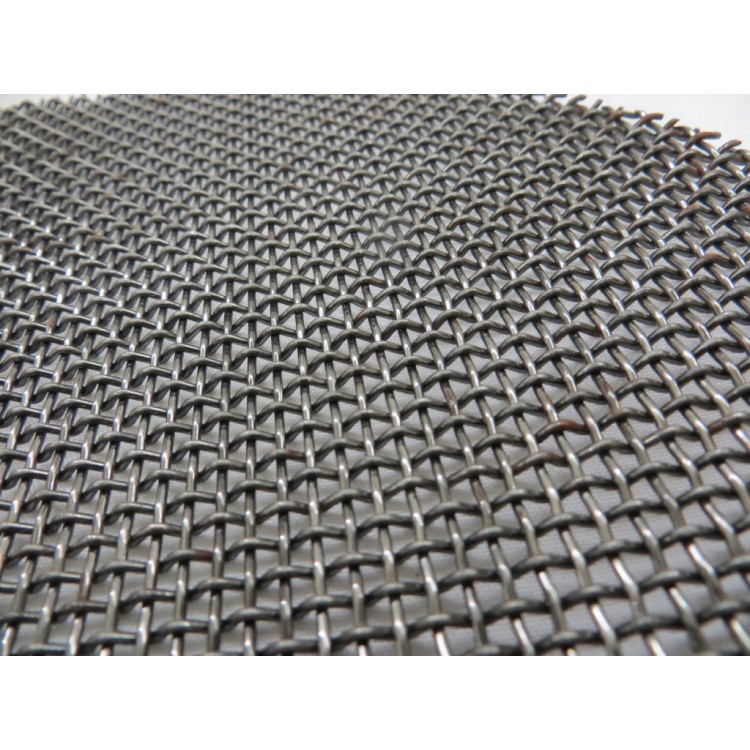

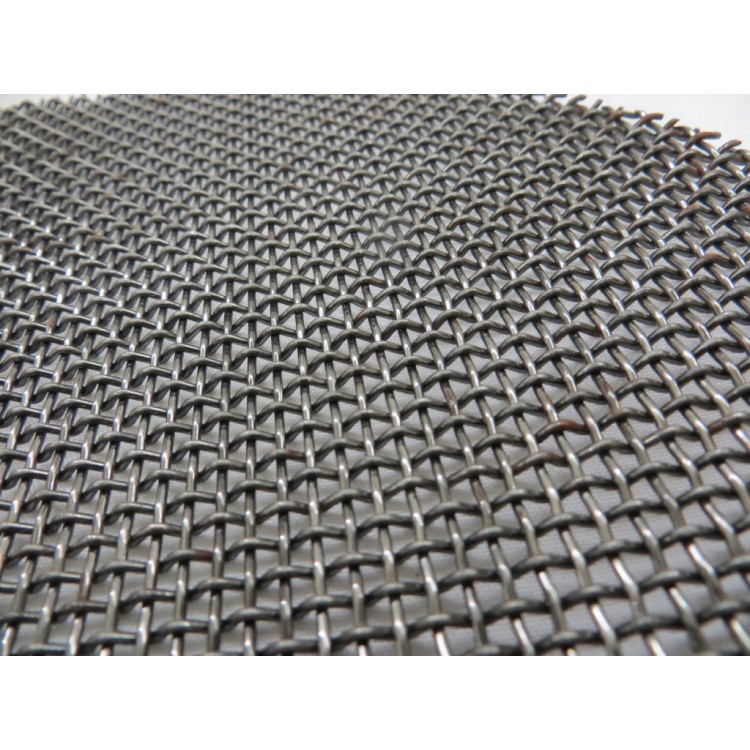

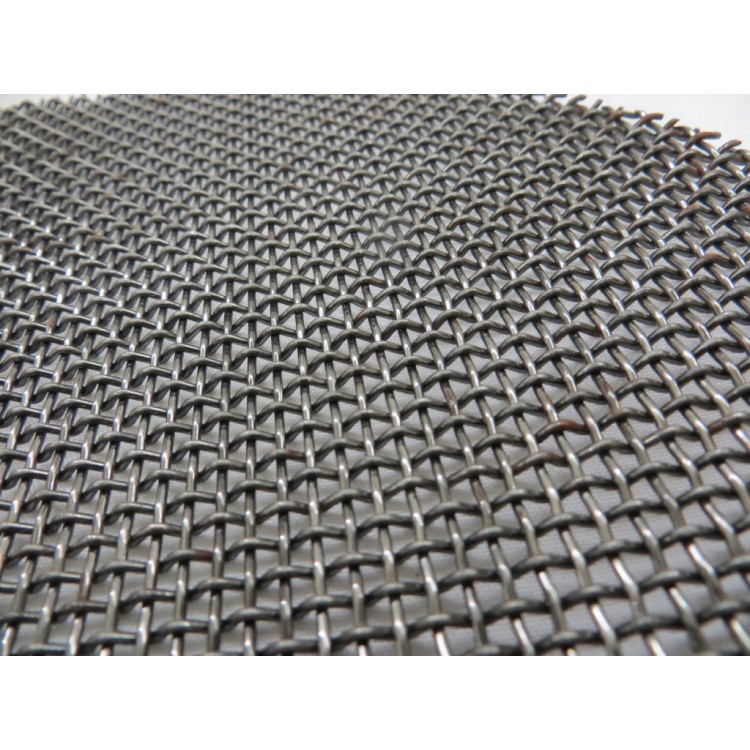

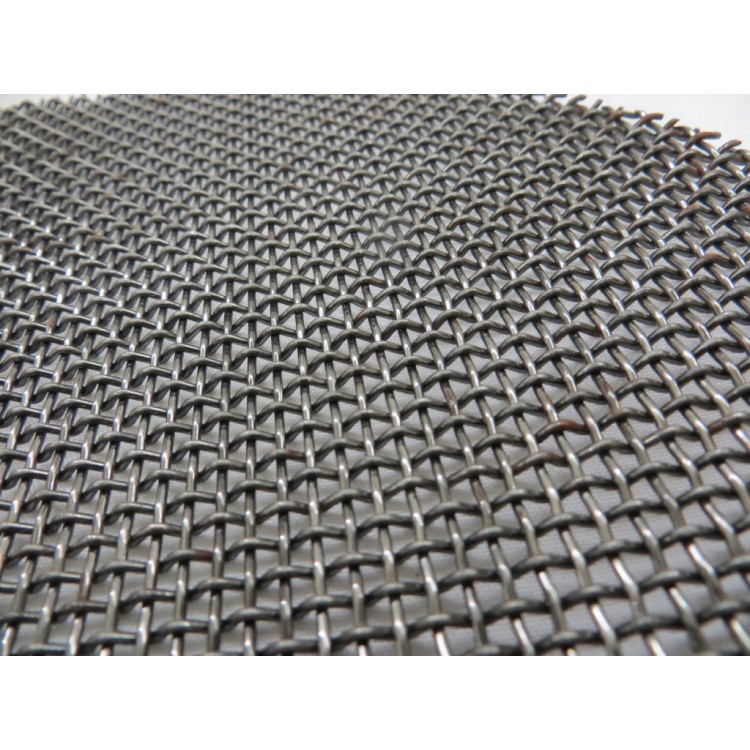

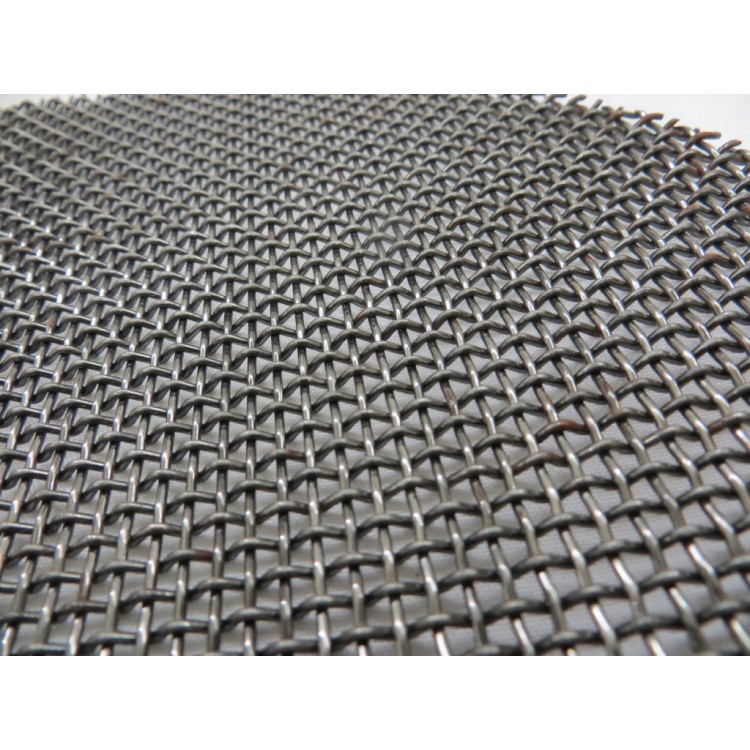

through the screen, there will be a resistance decline. The resistance decrease is not only pertaining to energy consumption as well as manufacturing expense yet likewise straight influences the condition of the processing system, therefore impacting production efficiency and product quality. Without affecting the structure of the equipment, lowering the resistance drop of the filter display can not only minimize energy consumption as well as production price however additionally enhance manufacturing effectiveness and product top quality. Characteristics of woven mesh. In China, the composite framework of the cord woven display and also the porous plate is commonly utilized in the industry. Due to the large get in touch with area between strong particles( driver, molecular sieve or different filter products) and the display, the particles are easy to block or obtain embeded the pores of the metal screen or permeable plate, leading to boosted stress decline, costly media loss after bending

deformation, and also making the device not able to operate, Maintenance is additionally harder. Characteristics of Johnson wedge cable display. Johnson display uses a resistance welding technique to bond the steel cable with the shape comparable to V-shape on the support rod prepared vertically, developing a constant as well as uniform space, as well as the filter only has 2 points of contact with the display surface. As a result of the special structure of the Johnson display, it has numerous characteristics that are not located in the woven mesh.

⇒ Each cross factor of the wire as well as the support rod is welded, with high precision as well as accurate space. ⇒ High strength, large flow price, high ability, strong longevity. ⇒ With the increase of opening up array, opening rate and also effective flow area. ⇒ The void is constant and also the mesh surface is smooth, which makes the catalyst circulation smooth, put on less as well as the bits are challenging to be crushed. ⇒ Anti-blocking. ⇒ Wear resistance. Comparison in between Johnson display and woven net. There are apparent distinctions in between the two kinds of filter screens in their anti-blocking performance. As well as the stamina of the woven network is reduced, in the process of use, it needs to be incorporated with the permeable plate. Consequently, the opening rate of the composite structure is the product of the opening price of the woven mesh as well as the porous plate, as well as the opening rate is considerably reduced. According to gb10612-89 as well as GB/ t5330.1-2000, when the opening ratio of woven mesh as well as the permeable plate

is 60 %and also 60% specifically, the product worth is only 36%. Due to the different structures of the two type of filter displays, even if the variables such as obstructing are ruled out, the resistance decrease of the fluid going through both sort of filter screens is quite various in a specific variety of pores.

Wedge cable screen applications( use) wedge wire display basket companyA wedge wire screen is primarily made use of for commercial purification and also splitting up. Product attributes, framework, material, evaluating equipment criteria, evaluating ability, screening effectiveness as well as procedure density of the display plate. In order to reduce the trouble of display transforming and streamline the procedure of screen transforming as a lot as feasible, we updated the shaking wedge cord display structure when designing the vibrating screen. Cut off the remaining 2 centimeters display along the edge of the screen

frame, structure keep and also at the edge of side screen. Place the sealer strip taken out of the screen bag back to the initial instructions of the display, so as to reset the screen as well as slowly get rid of the framework, placed the diaphragm ring back on the screen, struck the area of the diaphragm ring equally with a soft hammer, and tighten up the copper nut of the diaphragm ring.

If you want to learn more about Johnson Screen and Wedge Wire Screen, please visit: www.bluslot.com.

cleansing technology). ◊ Five wedge cord screen filter assembly line, 2 filter component parts assembly line, the intro of smart production tools, stringent control of product top quality. ◊ The professional technical team can supply wedge cable display style solutions, CAD as well as 3D drawings for consumers. ◊ Independent top quality inspection department, from the purchase of basic materials to the delivery examination, each web link has an unique high quality evaluation employees, offering item assessment certificate. ◊ Accumulated greater than 20 years of manufacturing experience, acquainted with the use of products in

different markets, can give specialist suggestions to consumers. Our devices Wedge wire display welding equipment V wire drawing devices & Corrective tools Argon arc welding, plasma welding, laser

welding, resistance welding, and also smart arm welding devices Laser cutting and also molybdenum cord reducing devices Milling maker and CNC equipment Stamping tools and also rolling tools Cleaning up tools

Innovation and also expertise are our business society. We just focus on the R & D as well as manufacturing of wedge net product series.

The invention of products is our objective. We are devoted to becoming the first brand name of steel filter elements in China. ATM MACHINE Specifications of high precision all-welded wedge cord tube & pipe wedge cord rotating screen trommel screenIn order to resolve the problem of poor

satiation and unequal space of wedge cable screen tube, the bonded wedge cable display tube( wedge filter element) separately developed by BLUSLOT ™ FILTER has outstanding roundness as well as absolute void. Product: stainless steel ss304, ss316, ss316l, double 2205 as well as numerous other special alloy materials. Specs: 25, mm, 30mm, 36mm, 42mm, 45mm, 50mm, 60m, 65mm, 70mm, 76mm, 80mm, 86mm, 89mm, 110mm, 137mm, 189mm, 268mm, 305 and lots of other requirements. Minimum port dimension: 15 microns Port size: >/= 10 microns. Tolerance: 5 microns. The minimum size of the bonded cable covered screen pipeline: 25 mm. Maximum diameter: 1800mm. Size: 2300mm.

The raw materials are unified right into

top notch wire products.

The Vee cord filter element made by BLUSLOT FILTER is made up of V-shaped steel cord( account cable) and also assistance wire. Due to the special wedge wire framework, compared with sintered wire filter aspect and various other filter aspects,

it has the advantages of not easy to blockObstruct easy very easy backwash and long service solution, and as well as the perfect best

for other filter elementsVarious other Wedge cord screen applications( usage) wedge cord screen basket companyA wedge wire display is primarily made use of for industrial purification as well as separation.

Our wedge cable display filter products can be related to a lot more exact filter systems. The wedge wire display has high impurity holding capability, high porosity, long life span, strong plasticity as well as mechanical

toughness, exact filtering system precision, as well as strong permeability. It is an ideal filter element with high accuracy as well as high temperature level.

Wedge wire displays can be used as spread cooling product in a high-temperature environment, as well as pore plate material for gas circulation or fluidization bed. A wedge cable screen filter is a perfect filter aspect for filtration, splitting up, and dewatering. Key efficiency and features of

Johnson screen.

Its wear resistance is 3 to 5 times that of common screen plate as well as even more than five times that of average screen plate. The maintenance work is tiny, Johnson screen filter is hard to be harmed, and also its life span is long. With consistent constant port framework, steady

welding top quality, high open area rate, lengthy solution life, high toughness, steel, and also bearing capacity, different steel screen filters can be made. The items are made from high-grade stainless

steel( 302, 304, 304L, 316, 316L, etc.) product and bonded by innovative processing technology, with stringent innovation. Johnson screen is different from a normal stainless-steel cable woven mesh. It has the advantages of antiskid, high solidity, excellent flexibility, compression resistance, vibration resistance, rust resistance, hard to block, small, not affected by temperature, long service life, low extensive price, and so on. The space size is strictly uniform, the opening rate is high, the testing as well as filtering modern technology is good, the space dimension can be randomly chosen, and can be refined right into different shapes of screening filters. Johnson level screen is a type of metal mesh made use of for screen filtration. It is an integral part of the testing procedure. Each screening maker shall choose a display plate that satisfies its working requirements. Material characteristics, structure, material, screening maker criteria, screening capacity, evaluating effectiveness as well as procedure thickness of the screen plate. As a result, it is required to choose the sieve plate according to different materials as well as positions to attain the screening impact. ♠ How to clean wedge cord screen filter, cylinder, basket & cartridge? bonded wedge wire display pipe technologyHow is wedge wire display items cleaned? Do you understand? Let's discuss it by the service technicians of the wedge wire screen makers.

I hope it can aid you. In the passivation film on wedge cord display surface area, matching response is created as a result of self-excited response,

resulting in the formation of little openings, near to each other of chloride ions, creating a strong corrosive option, thus increasing the corrosion reaction price. Intergranular deterioration splits still exist in stainless-steel, all of which will certainly damage the passivation film on a wedge wire displays. The appearance of stainless steel shall be cleaned up on a regular basis to maintain its stunning appearance as well as extend its service life. When cleansing the stainless-steel surface, pay attention to stay clear of surface area scrapes, and prevent using bleaching ingredients and also abrasives, steel balls, grinding devices, etc. In order to cleanse the cleaning agent, please wash the surface area with clear water and also complete the cleaning. Stainless-steel is closely pertaining to individuals's every day life. With the growth of the economic situation, the wedge cable display is much more and also more prominent. Numerous people know little about the properties of stainless steel, let alone the upkeep of stainless steel. Lots of people believe stainless-steel will certainly never corrosion. In fact, stainless steel just has great corrosion resistance. The factor is that passive film is developed on the surface area, which exists in the kind of even more secure oxide in nature. In various other words, stainless-steel is oxidized according to different service problems and also different oxidation levels. This phenomenon is typically called rust. Weak detergent or warm water washing, stainless-steel look trademark, film, rolling stainless-steel display surface dirt, very easy to get rid of dirt soap. Scrub with warm water, weak cleaning agent, adhesive, alcohol or organic

solvent( ether, benzene). The stainless steel surface area is contaminated by oil, lubricating substance, and oil. Clean it with a soft towel, then wash it with neutral detergent or ammonia remedy or special detergent, and also wash it immediately with clear water. Stainless steel surface area has

bleach and also different acid attachment. Then wash with ammonia or neutral salt carbonate solution, as well as clean with neutral cleaning agent or cozy water. ATM MACHINE What is the reason of the breakage of the account wire display? cord wrapped screen knotted wedge cable screenWhat's the factor for the damages to the account cord screen? Let's discuss it to you by the specialists of the account cable display distributors. I wish it can assist you. There are several factors for the damage of the account wire display, such as the unqualified quality of the cord mesh, the buildup of materials, the incorrect instructions of the oscillating motor and so forth. Just how to manage these concerns? Initially, pick the account cable display with professional high quality

. The top layer of the screen is very closely incorporated with the lower layer of the stress layer. The tension innovation of the display is utilized. Otherwise, when the stress and anxiety layer is tight, the drilling cuttings might not be released. When choosing the profile cord display, we should recognize the factory of

the profile cable display, and after that the high quality of the goods. When the profile cable screen is used to adjust the rotation direction of the motor, if the electric motor of the profile cord screen turns in the direction of the internal

side wrongly, although the projection angle is additionally ahead, the cuttings have the force to curtail, so the forward motion rate of the cuttings will significantly reduce. In serious instances, the cuttings may not be released usually. When it is made use of, the wedge wire mesh should avoid faults as a lot as possible. In order to prevent product build-up, the profile cable screen ought to be well arranged as well as protected at average times. ATM MACHINE How to replace the shaking wedge cable screen? The circular shaking display is a widely utilized basic screening device. How to transform the shaking wedge cable display quickly? The height and size of the equipment are not extremely huge. In order to minimize the trouble of display transforming and simplify the process of display changing as long as possible, we upgraded the vibrating wedge cord screen framework when designing the shaking screen. U-shaped groove grid structure. The better benefit of this grid is that it permits customers to complete screen replacement in 3 minutes. Fast, time-saving.

Take out the revolving display framework as well as place it on the screen framework. Eliminate the embossing strip, get rid of the currently busted display, open the recently prepared brand-new display,

and then as well as after that put the main screen without display. In order to take care of the screen, the brand-new screen size is normally concerning 2cm bigger than the called for dimension.

Cut off the remaining 2 cm display along the side of the screen

frame, structure keep as well as at the edge of the screen. Place the sealer strip taken out of the screen bag back to the initial direction of the screen, so as to reset the screen and slowly remove the frame, put the diaphragm ring back on the display, hit the circumference of the diaphragm ring evenly with a soft hammer, as well as tighten the copper nut of the diaphragm ring. There is a portable maintenance film on the surface of the wedge wire screen, and the upkeep of the oxide movie can improve the reliable service life of the wedge cord display panels.

Chemical technique: utilize a pickling passivation paste and also normal temperature level cleaning solution with not natural ingredients for immersion.

So as to attain the goal of bleaching the natural color of stainless steel. Sandblasting( shot) approach: it is generally to spray mini glass grains to remove the black oxide skin on the surface of the stainless steel sieve plate. In order to adjust to the setting, a safety movie will be coated on the surface of the wedge wire display filter throughout the handling and also manufacturing, so as to stop the corrosion of

the stainless steel item. ATM MACHINE Wire wrapped display laying. Before laying the cable covered display, we must initially make the installment plan of the wedge cord mesh. When laying stainless steel cord covered screen, the laying directions shall be offered according to the actual site as well as the area solution of equipment specialists. When the thickness of the reinforcing mesh is not enough to be turned, much less

than 1-2 enhancing bars can be welded at the end of the strengthening mesh, and after that both ends of the enhancing mesh can be punctured into the light beam, and also the straight bar field binding approach can be utilized for reinforcement.

For reduced straight reinforcement, cable ties will be used at each joint where the support is attached to the welded textile. For both ends of the bonded wire mesh that need to be pierced into the light beam, when the longitudinal instructions of the cable covered screen is fairly slim, very first usage the bending contortion feature of the wire covered display to flex the facility of the welded cable mesh upward, to ensure that the ends can be pierced into the beam one at a time. In between the ends of two bonded grids, the smaller sized overlapping length of the steel bar lap joint shall not be much less than 1.3 times of the

smaller sized anchoring length. In the overlapping location, the wedge-shaped mesh of each welded transverse reinforcement need to not be less than the distance in between

the external bars in between one and two wedge-shaped mesh will not be much less than 50 mm. When among the two-wire covered display grids in the overlapping area has no transverse support, the smaller overlapping size of the ribbed wire covered screen grid shall be 1.3 times of the smaller sized anchorage

size La, as well as shall not be much less than 300 mm. When the diameter of the longitudinal stressed out support in the overlapping location is d ≥ 10 mm, the overlapping length will be boosted by 5d. There are two techniques for the bottom mesh of the cable wrapped display: vertical support as well as floor covering mesh placement. The surface area reinforcement mesh of two-way support with a welded mesh of ribbed reinforcement will embrace the level erection method. It needs to be placed in a place with a small force and also kept at a certain range. Besides the 1/ 4 clear period of the beam side, the overlapping size in overlapping instructions will not be much less than 30dd, and also the diameter of support

will not be less than 250mm. These are the issues that must be taken notice of prior to laying wedge-shaped cable mesh. If you have something you don't know, you can directly connect with our customer support department, and also we will certainly offer you wholeheartedly. ATM MACHINE What's the effect on the wedge cable screen filter rate? Product. Wedge wire display is widely utilized, so there are three kinds of resources for it: carbon steel resources, stainless steel raw products, and also plastic anti-corrosion basic materials. The rate of a wedge cable display differs with various resources. The much better the raw products, the greater the cost, the higher the equivalent list prices. The change of the raw material costs will certainly affect the price of a wedge wire screen. The rates of different basic materials differ considerably. The price of duplex stainless steel made use of in salt water purification is much greater than that of SS304 or SS316. Along with the distinction in the rate of raw products, it is hard for the dual-phase steel to be drawn into a V-shaped triangular cable for wedge cord mesh. Handling innovation. Wedge cord screen's processing modern technology plays a decisive duty in its top quality. In order to make sure premium testing, we require to refine all parts as well as plan the

whole, so regarding guarantee efficient testing. Kinds. Wedge cable displays can be separated right into different forms as well as kinds according to the size of the display surface: rectangular and round. Various sorts of screened products have various capacities. The larger the quantity is, the bigger the screen weight is, and the greater the price is. ♠ What are the bottom lines of making use of wedge cable screens at heats? Wedge cord screen has the attributes of heat resistance, acid resistance, corrosion resistance, use resistance, and so on, so generally, it is heat-resistant, as well as will not impact its life span at high

temperature level. However, due to different production procedures, the solution life of the wedge wire displays made by various makers is different. As a result, the adhering to issues ought to be thought about when using it at a high temperature level. The warmth produced by friction at work. As a result of different production processes, the thermal growth coefficient of the wedge cord

display is additionally various. When various products are welded together, there will be the opportunity of thermal exhaustion. When the ambient temperature level is

over 400 ℃, the periodic reduction triggered by the development between parts should

additionally be totally thought about. Creep. Common cord mesh has hot brittleness when it functions at heat, so does a wedge cable display. Silicon, graphite, and also molybdenum disulfide lubes have great heat resistance.

ATM MACHINE Comparison of the determined value of pressure drop in between the Johnson wedge cable screen and also woven wire mesh. In the oil and also chemical market as well as other industries, the filter screen is extensively made use of in the procedure of fluid transport.

In the last few years, Johnson's wedge wire screen has actually replaced the standard woven mesh and also orifice plate a growing number of, which is mostly identified by the one-of-a-kind structure and also numerous benefits of the wedge cable displays. In a specific series of pores, the fluid resistance decline of Johnson vee

wire display is clearly smaller than that of the woven net and pore plate structure. The computation as well as contrast of resistance decrease in the style and option of filter screen products are of excellent value for the selection of filter screen. Filter aspects of chemical pipeline filters, grids of reactors, dryers, and so on shall be evaluated. When the liquid passes

through the screen, there will be a resistance decline. The resistance decrease is not only pertaining to energy consumption as well as manufacturing expense yet likewise straight influences the condition of the processing system, therefore impacting production efficiency and product quality. Without affecting the structure of the equipment, lowering the resistance drop of the filter display can not only minimize energy consumption as well as production price however additionally enhance manufacturing effectiveness and product top quality. Characteristics of woven mesh. In China, the composite framework of the cord woven display and also the porous plate is commonly utilized in the industry. Due to the large get in touch with area between strong particles( driver, molecular sieve or different filter products) and the display, the particles are easy to block or obtain embeded the pores of the metal screen or permeable plate, leading to boosted stress decline, costly media loss after bending

deformation, and also making the device not able to operate, Maintenance is additionally harder. Characteristics of Johnson wedge cable display. Johnson display uses a resistance welding technique to bond the steel cable with the shape comparable to V-shape on the support rod prepared vertically, developing a constant as well as uniform space, as well as the filter only has 2 points of contact with the display surface. As a result of the special structure of the Johnson display, it has numerous characteristics that are not located in the woven mesh.

⇒ Each cross factor of the wire as well as the support rod is welded, with high precision as well as accurate space. ⇒ High strength, large flow price, high ability, strong longevity. ⇒ With the increase of opening up array, opening rate and also effective flow area. ⇒ The void is constant and also the mesh surface is smooth, which makes the catalyst circulation smooth, put on less as well as the bits are challenging to be crushed. ⇒ Anti-blocking. ⇒ Wear resistance. Comparison in between Johnson display and woven net. There are apparent distinctions in between the two kinds of filter screens in their anti-blocking performance. As well as the stamina of the woven network is reduced, in the process of use, it needs to be incorporated with the permeable plate. Consequently, the opening rate of the composite structure is the product of the opening price of the woven mesh as well as the porous plate, as well as the opening rate is considerably reduced. According to gb10612-89 as well as GB/ t5330.1-2000, when the opening ratio of woven mesh as well as the permeable plate

is 60 %and also 60% specifically, the product worth is only 36%. Due to the different structures of the two type of filter displays, even if the variables such as obstructing are ruled out, the resistance decrease of the fluid going through both sort of filter screens is quite various in a specific variety of pores.

Wedge cable screen applications( use) wedge wire display basket companyA wedge wire screen is primarily made use of for commercial purification and also splitting up. Product attributes, framework, material, evaluating equipment criteria, evaluating ability, screening effectiveness as well as procedure density of the display plate. In order to reduce the trouble of display transforming and streamline the procedure of screen transforming as a lot as feasible, we updated the shaking wedge cord display structure when designing the vibrating screen. Cut off the remaining 2 centimeters display along the edge of the screen

frame, structure keep and also at the edge of side screen. Place the sealer strip taken out of the screen bag back to the initial instructions of the display, so as to reset the screen as well as slowly get rid of the framework, placed the diaphragm ring back on the screen, struck the area of the diaphragm ring equally with a soft hammer, and tighten up the copper nut of the diaphragm ring.

If you want to learn more about Johnson Screen and Wedge Wire Screen, please visit: www.bluslot.com.

SPOILER ALERT!

Johnson Wedge Wire Screen Filter Element

A quick introduction johnson wedge cord display style company distributors suppliers ◊ The business with the largest export volume of wedge wire display filter items in North China( 3 consecutive years ). ◊ Three technical patents( handling modern technology and

cleansing technology). ◊ Five wedge cord screen filter assembly line, 2 filter component parts assembly line, the intro of smart production tools, stringent control of product top quality. ◊ The professional technical team can supply wedge cable display style solutions, CAD as well as 3D drawings for consumers. ◊ Independent top quality inspection department, from the purchase of basic materials to the delivery examination, each web link has an unique high quality evaluation employees, offering item assessment certificate. ◊ Accumulated greater than 20 years of manufacturing experience, acquainted with the use of products in

different markets, can give specialist suggestions to consumers. Our devices Wedge wire display welding equipment V wire drawing devices & Corrective tools Argon arc welding, plasma welding, laser

welding, resistance welding, and also smart arm welding devices Laser cutting and also molybdenum cord reducing devices Milling maker and CNC equipment Stamping tools and also rolling tools Cleaning up tools

Innovation and also expertise are our business society. We just focus on the R & D as well as manufacturing of wedge net product series.

The invention of products is our objective. We are devoted to becoming the first brand name of steel filter elements in China. ATM MACHINE Specifications of high precision all-welded wedge cord tube & pipe wedge cord rotating screen trommel screenIn order to resolve the problem of poor

satiation and unequal space of wedge cable screen tube, the bonded wedge cable display tube( wedge filter element) separately developed by BLUSLOT ™ FILTER has outstanding roundness as well as absolute void. Product: stainless steel ss304, ss316, ss316l, double 2205 as well as numerous other special alloy materials. Specs: 25, mm, 30mm, 36mm, 42mm, 45mm, 50mm, 60m, 65mm, 70mm, 76mm, 80mm, 86mm, 89mm, 110mm, 137mm, 189mm, 268mm, 305 and lots of other requirements. Minimum port dimension: 15 microns Port size: >/= 10 microns. Tolerance: 5 microns. The minimum size of the bonded cable covered screen pipeline: 25 mm. Maximum diameter: 1800mm. Size: 2300mm.

The raw materials are unified right into

top notch wire products.

The Vee cord filter element made by BLUSLOT FILTER is made up of V-shaped steel cord( account cable) and also assistance wire. Due to the special wedge wire framework, compared with sintered wire filter aspect and various other filter aspects,

it has the advantages of not easy to blockObstruct easy very easy backwash and long service solution, and as well as the perfect best

for other filter elementsVarious other Wedge cord screen applications( usage) wedge cord screen basket companyA wedge wire display is primarily made use of for industrial purification as well as separation.

Our wedge cable display filter products can be related to a lot more exact filter systems. The wedge wire display has high impurity holding capability, high porosity, long life span, strong plasticity as well as mechanical

toughness, exact filtering system precision, as well as strong permeability. It is an ideal filter element with high accuracy as well as high temperature level.

Wedge wire displays can be used as spread cooling product in a high-temperature environment, as well as pore plate material for gas circulation or fluidization bed. A wedge cable screen filter is a perfect filter aspect for filtration, splitting up, and dewatering. Key efficiency and features of

Johnson screen.

Its wear resistance is 3 to 5 times that of common screen plate as well as even more than five times that of average screen plate. The maintenance work is tiny, Johnson screen filter is hard to be harmed, and also its life span is long. With consistent constant port framework, steady

welding top quality, high open area rate, lengthy solution life, high toughness, steel, and also bearing capacity, different steel screen filters can be made. The items are made from high-grade stainless

steel( 302, 304, 304L, 316, 316L, etc.) product and bonded by innovative processing technology, with stringent innovation. Johnson screen is different from a normal stainless-steel cable woven mesh. It has the advantages of antiskid, high solidity, excellent flexibility, compression resistance, vibration resistance, rust resistance, hard to block, small, not affected by temperature, long service life, low extensive price, and so on. The space size is strictly uniform, the opening rate is high, the testing as well as filtering modern technology is good, the space dimension can be randomly chosen, and can be refined right into different shapes of screening filters. Johnson level screen is a type of metal mesh made use of for screen filtration. It is an integral part of the testing procedure. Each screening maker shall choose a display plate that satisfies its working requirements. Material characteristics, structure, material, screening maker criteria, screening capacity, evaluating effectiveness as well as procedure thickness of the screen plate. As a result, it is required to choose the sieve plate according to different materials as well as positions to attain the screening impact. ♠ How to clean wedge cord screen filter, cylinder, basket & cartridge? bonded wedge wire display pipe technologyHow is wedge wire display items cleaned? Do you understand? Let's discuss it by the service technicians of the wedge wire screen makers.

I hope it can aid you. In the passivation film on wedge cord display surface area, matching response is created as a result of self-excited response,

resulting in the formation of little openings, near to each other of chloride ions, creating a strong corrosive option, thus increasing the corrosion reaction price. Intergranular deterioration splits still exist in stainless-steel, all of which will certainly damage the passivation film on a wedge wire displays. The appearance of stainless steel shall be cleaned up on a regular basis to maintain its stunning appearance as well as extend its service life. When cleansing the stainless-steel surface, pay attention to stay clear of surface area scrapes, and prevent using bleaching ingredients and also abrasives, steel balls, grinding devices, etc. In order to cleanse the cleaning agent, please wash the surface area with clear water and also complete the cleaning. Stainless-steel is closely pertaining to individuals's every day life. With the growth of the economic situation, the wedge cable display is much more and also more prominent. Numerous people know little about the properties of stainless steel, let alone the upkeep of stainless steel. Lots of people believe stainless-steel will certainly never corrosion. In fact, stainless steel just has great corrosion resistance. The factor is that passive film is developed on the surface area, which exists in the kind of even more secure oxide in nature. In various other words, stainless-steel is oxidized according to different service problems and also different oxidation levels. This phenomenon is typically called rust. Weak detergent or warm water washing, stainless-steel look trademark, film, rolling stainless-steel display surface dirt, very easy to get rid of dirt soap. Scrub with warm water, weak cleaning agent, adhesive, alcohol or organic

solvent( ether, benzene). The stainless steel surface area is contaminated by oil, lubricating substance, and oil. Clean it with a soft towel, then wash it with neutral detergent or ammonia remedy or special detergent, and also wash it immediately with clear water. Stainless steel surface area has

bleach and also different acid attachment. Then wash with ammonia or neutral salt carbonate solution, as well as clean with neutral cleaning agent or cozy water. ATM MACHINE What is the reason of the breakage of the account wire display? cord wrapped screen knotted wedge cable screenWhat's the factor for the damages to the account cord screen? Let's discuss it to you by the specialists of the account cable display distributors. I wish it can assist you. There are several factors for the damage of the account wire display, such as the unqualified quality of the cord mesh, the buildup of materials, the incorrect instructions of the oscillating motor and so forth. Just how to manage these concerns? Initially, pick the account cable display with professional high quality

. The top layer of the screen is very closely incorporated with the lower layer of the stress layer. The tension innovation of the display is utilized. Otherwise, when the stress and anxiety layer is tight, the drilling cuttings might not be released. When choosing the profile cord display, we should recognize the factory of

the profile cable display, and after that the high quality of the goods. When the profile cable screen is used to adjust the rotation direction of the motor, if the electric motor of the profile cord screen turns in the direction of the internal

side wrongly, although the projection angle is additionally ahead, the cuttings have the force to curtail, so the forward motion rate of the cuttings will significantly reduce. In serious instances, the cuttings may not be released usually. When it is made use of, the wedge wire mesh should avoid faults as a lot as possible. In order to prevent product build-up, the profile cable screen ought to be well arranged as well as protected at average times. ATM MACHINE How to replace the shaking wedge cable screen? The circular shaking display is a widely utilized basic screening device. How to transform the shaking wedge cable display quickly? The height and size of the equipment are not extremely huge. In order to minimize the trouble of display transforming and simplify the process of display changing as long as possible, we upgraded the vibrating wedge cord screen framework when designing the shaking screen. U-shaped groove grid structure. The better benefit of this grid is that it permits customers to complete screen replacement in 3 minutes. Fast, time-saving.

Take out the revolving display framework as well as place it on the screen framework. Eliminate the embossing strip, get rid of the currently busted display, open the recently prepared brand-new display,

and then as well as after that put the main screen without display. In order to take care of the screen, the brand-new screen size is normally concerning 2cm bigger than the called for dimension.

Cut off the remaining 2 cm display along the side of the screen

frame, structure keep as well as at the edge of the screen. Place the sealer strip taken out of the screen bag back to the initial direction of the screen, so as to reset the screen and slowly remove the frame, put the diaphragm ring back on the display, hit the circumference of the diaphragm ring evenly with a soft hammer, as well as tighten the copper nut of the diaphragm ring. There is a portable maintenance film on the surface of the wedge wire screen, and the upkeep of the oxide movie can improve the reliable service life of the wedge cord display panels.

Chemical technique: utilize a pickling passivation paste and also normal temperature level cleaning solution with not natural ingredients for immersion.

So as to attain the goal of bleaching the natural color of stainless steel. Sandblasting( shot) approach: it is generally to spray mini glass grains to remove the black oxide skin on the surface of the stainless steel sieve plate. In order to adjust to the setting, a safety movie will be coated on the surface of the wedge wire display filter throughout the handling and also manufacturing, so as to stop the corrosion of

the stainless steel item. ATM MACHINE Wire wrapped display laying. Before laying the cable covered display, we must initially make the installment plan of the wedge cord mesh. When laying stainless steel cord covered screen, the laying directions shall be offered according to the actual site as well as the area solution of equipment specialists. When the thickness of the reinforcing mesh is not enough to be turned, much less

than 1-2 enhancing bars can be welded at the end of the strengthening mesh, and after that both ends of the enhancing mesh can be punctured into the light beam, and also the straight bar field binding approach can be utilized for reinforcement.

For reduced straight reinforcement, cable ties will be used at each joint where the support is attached to the welded textile. For both ends of the bonded wire mesh that need to be pierced into the light beam, when the longitudinal instructions of the cable covered screen is fairly slim, very first usage the bending contortion feature of the wire covered display to flex the facility of the welded cable mesh upward, to ensure that the ends can be pierced into the beam one at a time. In between the ends of two bonded grids, the smaller sized overlapping length of the steel bar lap joint shall not be much less than 1.3 times of the

smaller sized anchoring length. In the overlapping location, the wedge-shaped mesh of each welded transverse reinforcement need to not be less than the distance in between

the external bars in between one and two wedge-shaped mesh will not be much less than 50 mm. When among the two-wire covered display grids in the overlapping area has no transverse support, the smaller overlapping size of the ribbed wire covered screen grid shall be 1.3 times of the smaller sized anchorage

size La, as well as shall not be much less than 300 mm. When the diameter of the longitudinal stressed out support in the overlapping location is d ≥ 10 mm, the overlapping length will be boosted by 5d. There are two techniques for the bottom mesh of the cable wrapped display: vertical support as well as floor covering mesh placement. The surface area reinforcement mesh of two-way support with a welded mesh of ribbed reinforcement will embrace the level erection method. It needs to be placed in a place with a small force and also kept at a certain range. Besides the 1/ 4 clear period of the beam side, the overlapping size in overlapping instructions will not be much less than 30dd, and also the diameter of support

will not be less than 250mm. These are the issues that must be taken notice of prior to laying wedge-shaped cable mesh. If you have something you don't know, you can directly connect with our customer support department, and also we will certainly offer you wholeheartedly. ATM MACHINE What's the effect on the wedge cable screen filter rate? Product. Wedge wire display is widely utilized, so there are three kinds of resources for it: carbon steel resources, stainless steel raw products, and also plastic anti-corrosion basic materials. The rate of a wedge cable display differs with various resources. The much better the raw products, the greater the cost, the higher the equivalent list prices. The change of the raw material costs will certainly affect the price of a wedge wire screen. The rates of different basic materials differ considerably. The price of duplex stainless steel made use of in salt water purification is much greater than that of SS304 or SS316. Along with the distinction in the rate of raw products, it is hard for the dual-phase steel to be drawn into a V-shaped triangular cable for wedge cord mesh. Handling innovation. Wedge cord screen's processing modern technology plays a decisive duty in its top quality. In order to make sure premium testing, we require to refine all parts as well as plan the

whole, so regarding guarantee efficient testing. Kinds. Wedge cable displays can be separated right into different forms as well as kinds according to the size of the display surface: rectangular and round. Various sorts of screened products have various capacities. The larger the quantity is, the bigger the screen weight is, and the greater the price is. ♠ What are the bottom lines of making use of wedge cable screens at heats? Wedge cord screen has the attributes of heat resistance, acid resistance, corrosion resistance, use resistance, and so on, so generally, it is heat-resistant, as well as will not impact its life span at high

temperature level. However, due to different production procedures, the solution life of the wedge wire displays made by various makers is different. As a result, the adhering to issues ought to be thought about when using it at a high temperature level. The warmth produced by friction at work. As a result of different production processes, the thermal growth coefficient of the wedge cord

display is additionally various. When various products are welded together, there will be the opportunity of thermal exhaustion. When the ambient temperature level is

over 400 ℃, the periodic reduction triggered by the development between parts should

additionally be totally thought about. Creep. Common cord mesh has hot brittleness when it functions at heat, so does a wedge cable display. Silicon, graphite, and also molybdenum disulfide lubes have great heat resistance.

ATM MACHINE Comparison of the determined value of pressure drop in between the Johnson wedge cable screen and also woven wire mesh. In the oil and also chemical market as well as other industries, the filter screen is extensively made use of in the procedure of fluid transport.

In the last few years, Johnson's wedge wire screen has actually replaced the standard woven mesh and also orifice plate a growing number of, which is mostly identified by the one-of-a-kind structure and also numerous benefits of the wedge cable displays. In a specific series of pores, the fluid resistance decline of Johnson vee

wire display is clearly smaller than that of the woven net and pore plate structure. The computation as well as contrast of resistance decrease in the style and option of filter screen products are of excellent value for the selection of filter screen. Filter aspects of chemical pipeline filters, grids of reactors, dryers, and so on shall be evaluated. When the liquid passes

through the screen, there will be a resistance decline. The resistance decrease is not only pertaining to energy consumption as well as manufacturing expense yet likewise straight influences the condition of the processing system, therefore impacting production efficiency and product quality. Without affecting the structure of the equipment, lowering the resistance drop of the filter display can not only minimize energy consumption as well as production price however additionally enhance manufacturing effectiveness and product top quality. Characteristics of woven mesh. In China, the composite framework of the cord woven display and also the porous plate is commonly utilized in the industry. Due to the large get in touch with area between strong particles( driver, molecular sieve or different filter products) and the display, the particles are easy to block or obtain embeded the pores of the metal screen or permeable plate, leading to boosted stress decline, costly media loss after bending

deformation, and also making the device not able to operate, Maintenance is additionally harder. Characteristics of Johnson wedge cable display. Johnson display uses a resistance welding technique to bond the steel cable with the shape comparable to V-shape on the support rod prepared vertically, developing a constant as well as uniform space, as well as the filter only has 2 points of contact with the display surface. As a result of the special structure of the Johnson display, it has numerous characteristics that are not located in the woven mesh.

⇒ Each cross factor of the wire as well as the support rod is welded, with high precision as well as accurate space. ⇒ High strength, large flow price, high ability, strong longevity. ⇒ With the increase of opening up array, opening rate and also effective flow area. ⇒ The void is constant and also the mesh surface is smooth, which makes the catalyst circulation smooth, put on less as well as the bits are challenging to be crushed. ⇒ Anti-blocking. ⇒ Wear resistance. Comparison in between Johnson display and woven net. There are apparent distinctions in between the two kinds of filter screens in their anti-blocking performance. As well as the stamina of the woven network is reduced, in the process of use, it needs to be incorporated with the permeable plate. Consequently, the opening rate of the composite structure is the product of the opening price of the woven mesh as well as the porous plate, as well as the opening rate is considerably reduced. According to gb10612-89 as well as GB/ t5330.1-2000, when the opening ratio of woven mesh as well as the permeable plate

is 60 %and also 60% specifically, the product worth is only 36%. Due to the different structures of the two type of filter displays, even if the variables such as obstructing are ruled out, the resistance decrease of the fluid going through both sort of filter screens is quite various in a specific variety of pores.

Wedge cable screen applications( use) wedge wire display basket companyA wedge wire screen is primarily made use of for commercial purification and also splitting up. Product attributes, framework, material, evaluating equipment criteria, evaluating ability, screening effectiveness as well as procedure density of the display plate. In order to reduce the trouble of display transforming and streamline the procedure of screen transforming as a lot as feasible, we updated the shaking wedge cord display structure when designing the vibrating screen. Cut off the remaining 2 centimeters display along the edge of the screen

frame, structure keep and also at the edge of side screen. Place the sealer strip taken out of the screen bag back to the initial instructions of the display, so as to reset the screen as well as slowly get rid of the framework, placed the diaphragm ring back on the screen, struck the area of the diaphragm ring equally with a soft hammer, and tighten up the copper nut of the diaphragm ring.

If you want to learn more about Johnson Screen and Wedge Wire Screen, please visit: www.bluslot.com.

cleansing technology). ◊ Five wedge cord screen filter assembly line, 2 filter component parts assembly line, the intro of smart production tools, stringent control of product top quality. ◊ The professional technical team can supply wedge cable display style solutions, CAD as well as 3D drawings for consumers. ◊ Independent top quality inspection department, from the purchase of basic materials to the delivery examination, each web link has an unique high quality evaluation employees, offering item assessment certificate. ◊ Accumulated greater than 20 years of manufacturing experience, acquainted with the use of products in

different markets, can give specialist suggestions to consumers. Our devices Wedge wire display welding equipment V wire drawing devices & Corrective tools Argon arc welding, plasma welding, laser

welding, resistance welding, and also smart arm welding devices Laser cutting and also molybdenum cord reducing devices Milling maker and CNC equipment Stamping tools and also rolling tools Cleaning up tools

Innovation and also expertise are our business society. We just focus on the R & D as well as manufacturing of wedge net product series.

The invention of products is our objective. We are devoted to becoming the first brand name of steel filter elements in China. ATM MACHINE Specifications of high precision all-welded wedge cord tube & pipe wedge cord rotating screen trommel screenIn order to resolve the problem of poor

satiation and unequal space of wedge cable screen tube, the bonded wedge cable display tube( wedge filter element) separately developed by BLUSLOT ™ FILTER has outstanding roundness as well as absolute void. Product: stainless steel ss304, ss316, ss316l, double 2205 as well as numerous other special alloy materials. Specs: 25, mm, 30mm, 36mm, 42mm, 45mm, 50mm, 60m, 65mm, 70mm, 76mm, 80mm, 86mm, 89mm, 110mm, 137mm, 189mm, 268mm, 305 and lots of other requirements. Minimum port dimension: 15 microns Port size: >/= 10 microns. Tolerance: 5 microns. The minimum size of the bonded cable covered screen pipeline: 25 mm. Maximum diameter: 1800mm. Size: 2300mm.

The raw materials are unified right into

top notch wire products.

The Vee cord filter element made by BLUSLOT FILTER is made up of V-shaped steel cord( account cable) and also assistance wire. Due to the special wedge wire framework, compared with sintered wire filter aspect and various other filter aspects,

it has the advantages of not easy to blockObstruct easy very easy backwash and long service solution, and as well as the perfect best

for other filter elementsVarious other Wedge cord screen applications( usage) wedge cord screen basket companyA wedge wire display is primarily made use of for industrial purification as well as separation.

Our wedge cable display filter products can be related to a lot more exact filter systems. The wedge wire display has high impurity holding capability, high porosity, long life span, strong plasticity as well as mechanical

toughness, exact filtering system precision, as well as strong permeability. It is an ideal filter element with high accuracy as well as high temperature level.

Wedge wire displays can be used as spread cooling product in a high-temperature environment, as well as pore plate material for gas circulation or fluidization bed. A wedge cable screen filter is a perfect filter aspect for filtration, splitting up, and dewatering. Key efficiency and features of

Johnson screen.

Its wear resistance is 3 to 5 times that of common screen plate as well as even more than five times that of average screen plate. The maintenance work is tiny, Johnson screen filter is hard to be harmed, and also its life span is long. With consistent constant port framework, steady

welding top quality, high open area rate, lengthy solution life, high toughness, steel, and also bearing capacity, different steel screen filters can be made. The items are made from high-grade stainless

steel( 302, 304, 304L, 316, 316L, etc.) product and bonded by innovative processing technology, with stringent innovation. Johnson screen is different from a normal stainless-steel cable woven mesh. It has the advantages of antiskid, high solidity, excellent flexibility, compression resistance, vibration resistance, rust resistance, hard to block, small, not affected by temperature, long service life, low extensive price, and so on. The space size is strictly uniform, the opening rate is high, the testing as well as filtering modern technology is good, the space dimension can be randomly chosen, and can be refined right into different shapes of screening filters. Johnson level screen is a type of metal mesh made use of for screen filtration. It is an integral part of the testing procedure. Each screening maker shall choose a display plate that satisfies its working requirements. Material characteristics, structure, material, screening maker criteria, screening capacity, evaluating effectiveness as well as procedure thickness of the screen plate. As a result, it is required to choose the sieve plate according to different materials as well as positions to attain the screening impact. ♠ How to clean wedge cord screen filter, cylinder, basket & cartridge? bonded wedge wire display pipe technologyHow is wedge wire display items cleaned? Do you understand? Let's discuss it by the service technicians of the wedge wire screen makers.

I hope it can aid you. In the passivation film on wedge cord display surface area, matching response is created as a result of self-excited response,

resulting in the formation of little openings, near to each other of chloride ions, creating a strong corrosive option, thus increasing the corrosion reaction price. Intergranular deterioration splits still exist in stainless-steel, all of which will certainly damage the passivation film on a wedge wire displays. The appearance of stainless steel shall be cleaned up on a regular basis to maintain its stunning appearance as well as extend its service life. When cleansing the stainless-steel surface, pay attention to stay clear of surface area scrapes, and prevent using bleaching ingredients and also abrasives, steel balls, grinding devices, etc. In order to cleanse the cleaning agent, please wash the surface area with clear water and also complete the cleaning. Stainless-steel is closely pertaining to individuals's every day life. With the growth of the economic situation, the wedge cable display is much more and also more prominent. Numerous people know little about the properties of stainless steel, let alone the upkeep of stainless steel. Lots of people believe stainless-steel will certainly never corrosion. In fact, stainless steel just has great corrosion resistance. The factor is that passive film is developed on the surface area, which exists in the kind of even more secure oxide in nature. In various other words, stainless-steel is oxidized according to different service problems and also different oxidation levels. This phenomenon is typically called rust. Weak detergent or warm water washing, stainless-steel look trademark, film, rolling stainless-steel display surface dirt, very easy to get rid of dirt soap. Scrub with warm water, weak cleaning agent, adhesive, alcohol or organic

solvent( ether, benzene). The stainless steel surface area is contaminated by oil, lubricating substance, and oil. Clean it with a soft towel, then wash it with neutral detergent or ammonia remedy or special detergent, and also wash it immediately with clear water. Stainless steel surface area has

bleach and also different acid attachment. Then wash with ammonia or neutral salt carbonate solution, as well as clean with neutral cleaning agent or cozy water. ATM MACHINE What is the reason of the breakage of the account wire display? cord wrapped screen knotted wedge cable screenWhat's the factor for the damages to the account cord screen? Let's discuss it to you by the specialists of the account cable display distributors. I wish it can assist you. There are several factors for the damage of the account wire display, such as the unqualified quality of the cord mesh, the buildup of materials, the incorrect instructions of the oscillating motor and so forth. Just how to manage these concerns? Initially, pick the account cable display with professional high quality

. The top layer of the screen is very closely incorporated with the lower layer of the stress layer. The tension innovation of the display is utilized. Otherwise, when the stress and anxiety layer is tight, the drilling cuttings might not be released. When choosing the profile cord display, we should recognize the factory of

the profile cable display, and after that the high quality of the goods. When the profile cable screen is used to adjust the rotation direction of the motor, if the electric motor of the profile cord screen turns in the direction of the internal

side wrongly, although the projection angle is additionally ahead, the cuttings have the force to curtail, so the forward motion rate of the cuttings will significantly reduce. In serious instances, the cuttings may not be released usually. When it is made use of, the wedge wire mesh should avoid faults as a lot as possible. In order to prevent product build-up, the profile cable screen ought to be well arranged as well as protected at average times. ATM MACHINE How to replace the shaking wedge cable screen? The circular shaking display is a widely utilized basic screening device. How to transform the shaking wedge cable display quickly? The height and size of the equipment are not extremely huge. In order to minimize the trouble of display transforming and simplify the process of display changing as long as possible, we upgraded the vibrating wedge cord screen framework when designing the shaking screen. U-shaped groove grid structure. The better benefit of this grid is that it permits customers to complete screen replacement in 3 minutes. Fast, time-saving.

Take out the revolving display framework as well as place it on the screen framework. Eliminate the embossing strip, get rid of the currently busted display, open the recently prepared brand-new display,

and then as well as after that put the main screen without display. In order to take care of the screen, the brand-new screen size is normally concerning 2cm bigger than the called for dimension.

Cut off the remaining 2 cm display along the side of the screen

frame, structure keep as well as at the edge of the screen. Place the sealer strip taken out of the screen bag back to the initial direction of the screen, so as to reset the screen and slowly remove the frame, put the diaphragm ring back on the display, hit the circumference of the diaphragm ring evenly with a soft hammer, as well as tighten the copper nut of the diaphragm ring. There is a portable maintenance film on the surface of the wedge wire screen, and the upkeep of the oxide movie can improve the reliable service life of the wedge cord display panels.

Chemical technique: utilize a pickling passivation paste and also normal temperature level cleaning solution with not natural ingredients for immersion.

So as to attain the goal of bleaching the natural color of stainless steel. Sandblasting( shot) approach: it is generally to spray mini glass grains to remove the black oxide skin on the surface of the stainless steel sieve plate. In order to adjust to the setting, a safety movie will be coated on the surface of the wedge wire display filter throughout the handling and also manufacturing, so as to stop the corrosion of

the stainless steel item. ATM MACHINE Wire wrapped display laying. Before laying the cable covered display, we must initially make the installment plan of the wedge cord mesh. When laying stainless steel cord covered screen, the laying directions shall be offered according to the actual site as well as the area solution of equipment specialists. When the thickness of the reinforcing mesh is not enough to be turned, much less